The trouble of the sand factory owner?

In Shaanxi, a cobblestone sand factory owner is facing the pressure that the sand factory is about to lose money. As the factory equipment ages and operates poorly, it leads to low production efficiency, rising costs, and failure to meet environmental protection requirements. .....

The sand field uses pebbles as the main raw material for sand making, and the quality requirements for the sand making machine itself are too high. The boss requires improving production efficiency, reducing production costs and expanding production capacity. With this question, the owner of the sand factory asked multiple manufacturers, and finally compared brands, prices, performance, etc., and after in-depth communication and on-site inspections, he finally decisively chose Yuhui Heavy Industry!

How to solve and improve?

After learning about the boss's demands, our company immediately sent a professional team of engineers to your company for an on-site inspection and found that the current problems in the sand plant cannot be underestimated. The main problems are as follows:

01Production efficiency decreases and energy consumption increases

Because at present, some equipment such as sand making machines and feeders in the factory are seriously aging, parts are severely worn, operating efficiency is reduced, and production capacity is reduced, thus affecting the efficiency of the entire production line. The friction between machine parts increases, which leads to an increase in energy consumption, increases production costs, consumes electricity, and increases labor costs.

02 Material quality decline, noise and dust pollution

The aging sand making machine is seriously worn, the particle size distribution is uneven, the material quality is reduced, and the product quality is affected. During the operation of the machine, noise and dust pollution intensify due to the deterioration of equipment sealing. Environmental protection is not up to standard!

Because the technology of aging sand making machines may have lagged behind market demand and cannot meet product quality, output and other requirements.

With the cooperation and assistance of the owner of the sand factory, Yuhui Heavy Industry developed a tailor-made equipment replacement plan for the sand factory:

1 set of 4911 feeder

1 set of 1400 cone machine

2 sets of 3080 vibrating screens

2 sets of 3824 sand washing machines

1 set of 7501060 jaw crusher

2 sets of 2060 dehydration and recovery all-in-one machine

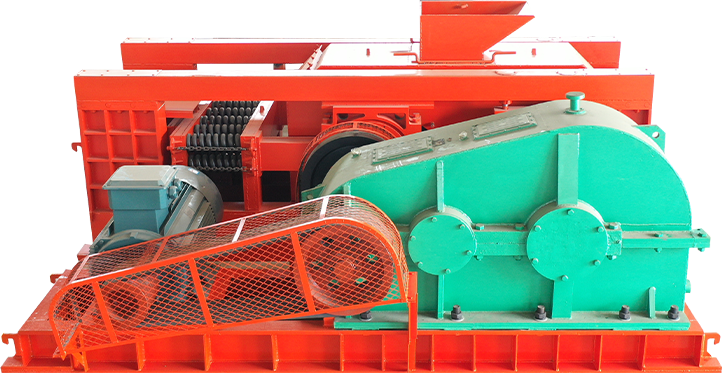

1 set of PGY16001000 roller sand making machine

Customer feedback after use

The effect of using Yuhui heavy industry equipment in sand factories

After using it for a period of time, I learned during a return visit that the current equipment can produce 220 to 250 tons of 5 mm machine-made sand per hour, and consumes only 1.68 kilowatt hours of electricity per ton. The smart display screen is easy to operate, which greatly reduces employee costs. The owner of the sand factory Very satisfied with the annual production of about 700,000 tons of machine-made sand!

Yuhui Heavy Industry will continue to follow up so that customers can use our machines with confidence and peace of mind. Help the sand factory create more value on this land!

選擇語言

選擇語言

Home

Home Product

Product Telephone

Telephone Message

Message