Infrastructure construction is mushrooming, and the demand for sand and gravel aggregates is also growing. However, traditional sand and gravel mining methods have caused serious damage to the environment. How to realize green and environmentally friendly sand making has become a top priority. Today, what we are going to share is: a successful case of a building materials company in Fujian using Yuhui double-roller sand to make machine-made sand. Let’s see how they turned the gravel generated by tunnel excavation into valuables and made sand and gravel bones that meet the requirements. material.

1. Background introduction:

In Fujian, there is a powerful building materials company that has been committed to providing high-quality sand and gravel aggregates for local infrastructure construction. The company uses gravel from tunnel excavation (usually called "tunnel slag") to make sand, which is composed of granite, and sieves the guar rice stone into the sand making machine. However, as the business develops, they find that the traditional sand making method has Unable to meet their needs, they urgently need an efficient, environmentally friendly and energy-saving sand making equipment.

2. Sand making problems:

The traditional sand making method is not only inefficient, but also causes serious damage to the environment. For this building materials company, they need to find a high-quality sand making machine that can not only meet a large number of sand making needs, but also meet national environmental protection requirements.

3. Performance and advantages of Yuhui Heavy Industry’s double-roller sand making machine:

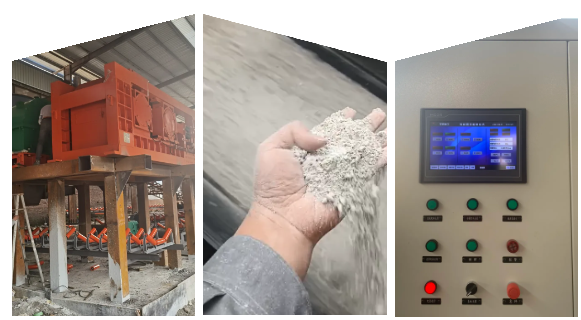

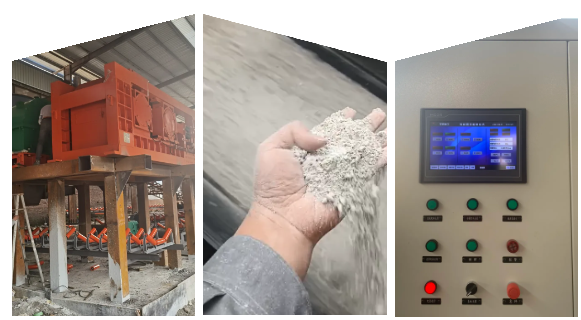

After multiple inspections and comparisons, the company chose Yuhui Heavy Industry’s PGY1300*700 hydraulic roller sand making machine. This sand making machine is like a powerful "Transformer" with the following advantages:

1. High efficiency and energy saving: PGY1300*700 hydraulic roller sand making machine adopts advanced technology and design, with a power of 315 kilowatts and can crush 150 tons of materials per hour, meeting the company's demand for output.

2. Environmentally friendly and low-carbon: The double-roller sand making machine has low noise and less dust during the sand making process, effectively reducing environmental pollution.

3. Strong adaptability: This equipment can crush a variety of materials, such as cobblestones, granite, limestone, etc., and the size of the crushed finished sand can be adjusted arbitrarily to meet the company's requirements for sand and gravel.

4. Easy maintenance: The roller sand making machine adopts hydraulic adjustment, which is easy to operate and maintain, reducing the company's operating costs.

4. Application effect and feedback:

Since the introduction of Yuhui Heavy Industry's PGY1300*700 hydraulic double-roller sand making machine, the company has used the gravel (cavity slag) generated by tunnel excavation to make sand, which not only solves environmental protection problems, but also improves resource utilization. During the sand making process, the equipment ran stably, the crushing effect was good, and the size of the finished sand met the requirements. It was highly praised by the company. It not only improved resource utilization and reduced environmental pollution, but also provided high-quality sand for local infrastructure construction. Stone aggregate. This successful case shows that Yuhui Heavy Industry's double-roller sand making machine is a sand making equipment with high efficiency, environmental protection, energy saving and other characteristics, and is worthy of promotion in the industry.

In the future, Yuhui Heavy Industry will continue to be committed to developing and producing better quality sand making equipment, assisting my country's infrastructure construction, and contributing to the development of green and environmentally friendly sand making industry.

選擇語(yǔ)言

選擇語(yǔ)言

Home

Home Product

Product Telephone

Telephone Message

Message