The double-roller sand making machine is a common mechanical equipment in metal smelting, casting, mining and other industries. Its working principle is to put the materials to be ground into the double-roller sand making machine. It is driven by a motor and drives two rollers through the axis. The rollers rotate in opposite directions to form a sanding surface, so that the materials are stirred, ground and dispersed.

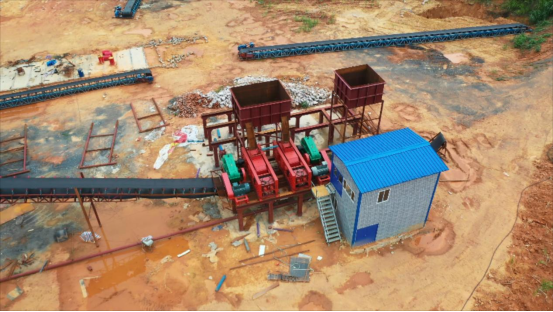

Currently, there are many types of double-roller sand making machines on the market, but they can be divided into multi-roller sand making machines and double-roller sand making machines according to the number of rollers. Among them, the double-roller sand making machine is used for relatively fine work such as fine grinding and wire drawing. The roller sand making machine can also be equipped with grinding wheels, baffles, mixers, reducers, safety devices and other equipment according to different needs to form a sand and gravel production line. Each sand making plant can consider its own capital investment, expected income, etc. to build a sand and gravel production line that suits its own development situation. Our company will also make professional suggestions based on customer needs.

The roller sand making machine has the advantages of compact structure, convenient operation and high production efficiency, and has been widely used in the sand and gravel production industry. In addition, since the sand making machine is mainly composed of motor, coupling, adjustment device, expansion sleeve, transmission shaft and lubrication, the daily maintenance of the roller sand making machine is also very important. Therefore, users should develop good human-machine collaboration habits and clean the equipment in a timely manner after use. They should also carefully check the condition of each component of the equipment before starting it up to ensure the safety and reliability of the machine.

選擇語言

選擇語言

Home

Home Product

Product Telephone

Telephone Message

Message