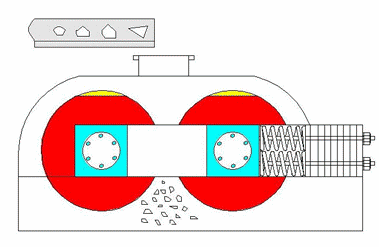

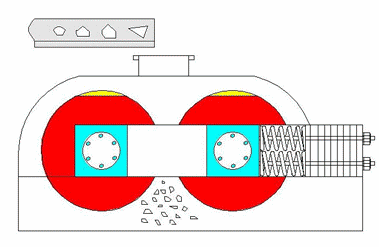

The fully automatic hydraulic double-roller sand making machine is actually an upgrade based on the commonly used mechanical pressure-regulating double-roller sand making machine. The hydraulic cylinder is used as the pressure output; the old-fashioned mechanical pressure regulating device is changed to a hydraulic device. After a period of use, the old-fashioned mechanical pressure-regulating roller sand making machine needs to manually adjust the pressure of the mechanical pressure-regulating device to meet various requirements for the finished product. The fully automatic hydraulic roller sand making machine is automatically adjusted through a hydraulic device, and the pressure adjustment is also more accurate. Except for the difference in the pressure structure, the structure and working principle of other parts of the hydraulic roller crusher are the same as those of the mechanical pressure-regulating roller sand making machine. The sand making work is still undertaken by two relatively rotating rollers.

The rollers of the roller sand making machine are wearing parts, and the quality of the rollers is directly related to the cost of production. Rollers of good quality are more wear-resistant and can last longer, causing fewer problems when the equipment is working. Subsequent maintenance costs will be lower and less energy will be consumed.

<

<

In addition, since the hydraulic device of a fully automatic hydraulic roller sand making machine is more expensive than the old-fashioned mechanical pressure regulating device, it is less cost-effective when applied to a small roller sand making machine, so the hydraulic device is usually used in On a large hydraulic roller crusher. Therefore, if we make a horizontal comparison, the large-scale fully automatic hydraulic roller sand making machine of the same specification is more expensive than the old-fashioned mechanical pressure-regulating roller sand making machine.

At present, the roller sand making machine market is a mixed bag. Some merchants do not have the production capacity and only assemble the various parts together. Therefore, the after-sales service of the products cannot be guaranteed at all. Therefore, customers should first investigate the strength and qualifications of the manufacturer before choosing a roller sand making machine. The follow-up service problem of sand making equipment is a pain point for many manufacturers. Good manufacturers can not only produce high-quality, high-value products; subsequent maintenance and repair of equipment will also make customers more worry-free and labor-saving. Choosing better products is also choosing better services from manufacturers.

選擇語言

選擇語言

<

<

Home

Home Product

Product Telephone

Telephone Message

Message